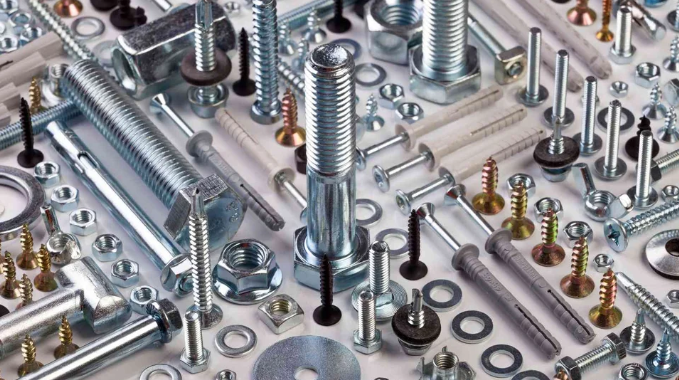

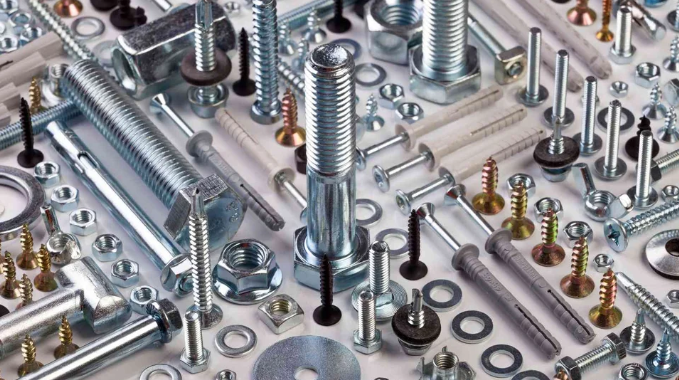

A fastener is any hardware device used to mechanically join or affix two or more components together. Fasteners come in a wide range of shapes and sizes, and they can be used for different applications across various industries. They provide the strength and stability needed to secure parts in place, preventing movement or separation under pressure.

The most common fasteners include screws, bolts, nuts, washers, rivets, clips, and pins, each of which serves a specific function depending on the application.

Types of Fasteners

There’s a fastener for nearly every situation, and the choice of fastener largely depends on the material being joined, the type of load, and the environmental conditions. Let’s explore some of the most popular types of fasteners:

Screws

Usage: Screws are one of the most versatile fasteners, used in everything from furniture assembly to industrial machinery.

Function: They work by threading into materials and creating a strong bond through friction.

Varieties: There are many types of screws, such as wood screws, machine screws, self-tapping screws, and sheet metal screws. Each is designed to work with a specific material.

Bolts and Nuts

Usage: Bolts and nuts are typically used in construction, automotive, and heavy machinery applications.

Function: Bolts are threaded and designed to pass through holes in components, while nuts are fasteners with internal threads that fit over the bolts, securing them in place.

Varieties: Common bolt types include hex bolts, carriage bolts, and anchor bolts.

Washers

Usage: Washers are used to distribute the load of a fastener, preventing damage to the surface of the material.

Function: They help provide even pressure across a fastener, reduce friction, and prevent loosening over time due to vibration.

Varieties: Flat washers, spring washers, and lock washers are some of the most common types.

Rivets

Usage: Rivets are often used in aerospace, automotive, and structural applications.

Function: Unlike screws and bolts, rivets are permanently fastened into place by deformation, making them ideal for joining materials that can't be easily removed or replaced.

Varieties: There are solid rivets, blind rivets, and tubular rivets, each suited for specific applications.

Pins

Usage: Pins are used to hold components in place or allow rotation (as in hinges).

Function: Pins are often used for precise positioning, and they come in a variety of styles, including cotter pins, roll pins, and dowel pins.

Varieties: Straight pins, spring pins, and tapered pins are among the most common options.

Clips

Usage: Clips are used to secure wires, cables, or other small components in place, often used in electrical systems.

Function: Clips provide a quick and easy way to attach or release parts without the need for tools.

Varieties: Retaining clips, spring clips, and circlips are commonly used in many mechanical and electrical systems.

Materials Used for Fasteners

The material of a fastener plays an essential role in its performance. Choosing the right material ensures durability, strength, and resistance to corrosion or wear. Here are some common materials used for fasteners:

Steel:

Steel fasteners are among the most common, offering strength and durability. Stainless steel, in particular, is highly resistant to corrosion and is ideal for outdoor and marine environments.

Aluminum:

Lightweight and corrosion-resistant, aluminum fasteners are used in applications where weight savings are crucial, such as in the aerospace industry.

Brass:

Brass fasteners are commonly used in electrical applications due to their excellent conductivity and resistance to corrosion.

Titanium:

Known for its strength and light weight, titanium fasteners are often used in high-performance applications such as aerospace and medical devices.

Plastic:

For applications that require non-conductive materials or resistance to chemical corrosion, plastic fasteners are commonly used.

Fasteners in Different Industries

Fasteners are critical components across various industries, and their design, function, and performance depend on the specific requirements of each sector. Let’s explore a few industries where fasteners play a crucial role:

Construction and Civil Engineering

In construction, fasteners are used to assemble everything from buildings to bridges and highways. They must be able to withstand heavy loads, extreme weather conditions, and wear over time. Bolts, nuts, washers, and rivets are frequently used in structural steel and concrete construction.

Automotive Industry

The automotive sector relies on fasteners to hold together critical components of vehicles. Fasteners in cars and trucks must be able to withstand vibrations, extreme temperatures, and pressure. Bolts, nuts, rivets, and clips are commonly used to assemble engines, suspension systems, body panels, and interior components.

Aerospace

Aerospace fasteners are designed to handle high-stress conditions and extreme temperatures. Titanium and high-strength steel fasteners are often used for parts that must be lightweight but incredibly strong. Additionally, specialized fasteners like lock bolts and blind rivets are essential for assembling the structure of aircraft and spacecraft.

Electronics

In the electronics industry, fasteners are used in everything from smartphones to computers. Here, fasteners often have to be small, lightweight, and non-corrosive, with an emphasis on easy assembly and disassembly for repairs and upgrades. Plastic fasteners, as well as screws and clips, are often used.

Furniture and Appliances

In furniture manufacturing, fasteners ensure that pieces are securely joined and provide structural integrity. Fasteners like screws, nails, and bolts are commonly used for assembling cabinets, tables, chairs, and large appliances such as refrigerators and washing machines.

Why Fasteners Matter

While fasteners may seem like simple hardware, they are essential for ensuring the safety, efficiency, and longevity of virtually every type of infrastructure, machinery, and product. Their role extends far beyond just keeping things together — they influence the overall performance, strength, and reliability of systems and structures.

In engineering and manufacturing, selecting the right fastener is critical, as the wrong choice could lead to product failure, accidents, or the need for costly repairs. For this reason, it's important to understand the various types of fasteners, their materials, and their applications to make informed choices that meet the demands of each project.